Case studies, Publications and software-news

Problem solutions, new approaches, further developments in simulation software and field reports from the world of virtual commissioning: Here you will find interesting reading on the subject of plant simulation and digital twins.

Case studies and field reports

Here you will find authentic case studies and testimonials from customers who are already successfully using fe.screen-sim to create digital twins.

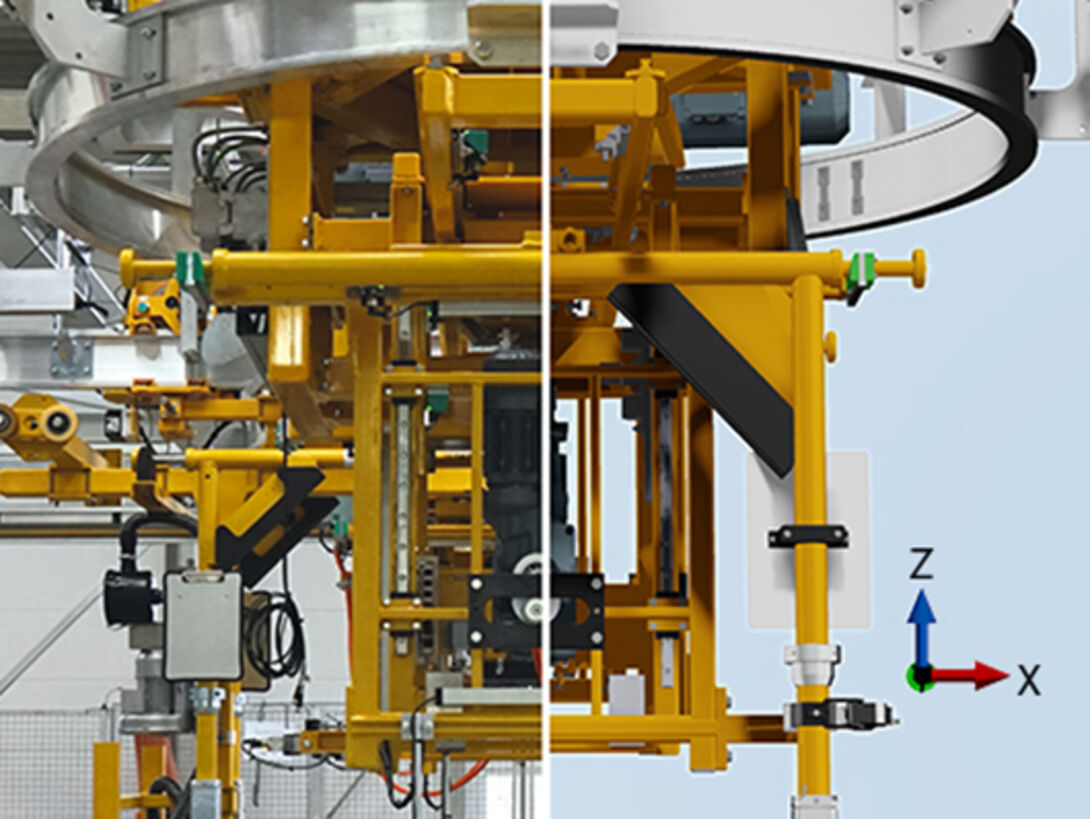

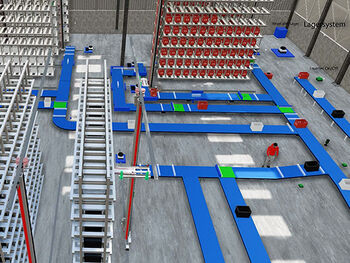

Successful plant conversion: A best practice example of successful virtual commissioning

The largest plant conversion in F.EE's history has been successfully completed at a leading car manufacturer – an impressive example of how virtual commissioning (VIBN) is revolutionising automation projects.

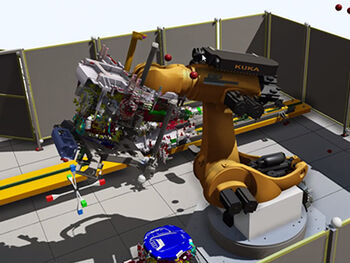

Schaeffler Special Machinery: Mehr PS durch virtuelle Inbetriebnahme

For over 75 years, the Schaeffler Group has been driving forward pioneering inventions and developments in the field of motion technology. Part of this success is to supply technologies, products and services to customers from a wide range of industrial sectors from a single source. Find out below how the virtual commissioning of systems with fe.screen-sim benefits the special machine manufacturer's customers.

"Virtual commissioning has become a success factor for us"

In this interview with Jörg Thomas - the technical manager of Klotz GmbH - you will learn how the use of the simulation software fe.screen-sim has positively influenced the workflow, why 90% of the company's plants are tested in advance by a digital twin and where the digital trends in engineering lie - which Klotz has already integrated into its processes.

Digital twins as a success factor in mechanical and plant engineering

Many companies from a wide range of industries are now faced with the decision to establish virtual commissioning and an associated software solution in their workflow. Inevitably, they are faced with the question of whether this project will bring the success and benefits they expect.

Publications and practical tips

Familiarise yourself with exciting information on the simulation tool and useful practical tips on fe.screen-sim.

Current whitepaper as a reading tip

„Virtual commissioning: methods, approach, benefits". Read our latest whitepaper and get more in-depth information on the topic of plant simulation and how to implement it.

Mechanical engineering of the future: How can the paradigm shift succeed?

Innovation up, costs down - AI in simulation, commissioning, operation and maintenance

Over the past 20 years, the automation specialist F.EE has continuously evolved in the fields of PLC simulation and process optimization. During this time, the software “fe.screen-sim“ was developed, which is now utilized by numerous companies for virtual commissioning. Although this simulation software is already highly effective, further advancements are on the horizon with the integration of artificial intelligence and digital twins.

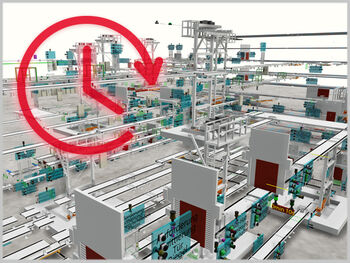

With high speed to the digital twin

In many companies today, the engineering process still follows a classic workflow. With regard to the ever advancing "digital engineering" as well as the associated workflow and data structure optimization, a rethinking must take place in the companies in order to continue to be successful on the market.

Virtual commissioning: efficiency increase and process optimization through direct data import

Especially in times of increasingly complex processes and short project lead times, many companies have recognized the advantages of virtual commissioning in terms of the associated time and cost savings.

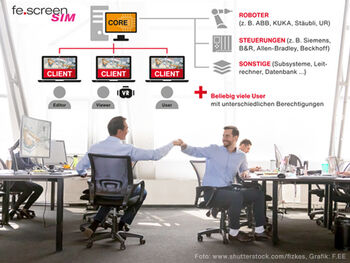

Reaching the goal together - With multi-user capability to efficient virtual commissioning

Multi-user capability – by which is meant the simultaneous work of several users on a simulation – has become a "game changer" in the creation of digital twins in terms of efficient working methods.

Virtual commissioning as a gamechanger in mechanical and plant engineering

In many companies, the engineering process follows a classic workflow: The development process of machines and plants is partly still sequentially structured. The electrical and mechanical design are sometimes carried out in parallel, and for the creation of the necessary control software for the PLCs and robots, the preconstruction is usually used as the environment for finalizing and securing the control technology. Due to global supply difficulties, problems can occur in the project process. Virtual commissioning can help to minimize their impact on the workflow.

46 Good reasons for plant simulation with fe.screen-sim

There are many reasons for using a simulation solution for digital plant twins.

Effective use of existing data sources to create digital twins

The increasingly complex engineering process in companies entails, among other things, a large and constantly growing number of software solutions.

Simulation as a data concentrator thanks to open interfaces

Many companies have a more or less large toolchain for their engineering process and miss the data consistency of the tools used. Media disruptions and information losses generate costs. In plant simulation, the data accumulated in the process is used to generate a digital twin.

Changing the engineering process through virtual commissioning

With the use of a solution for the creation of a digital twin, the workflow in the engineering process will change from a sequentially characterised workflow to parallel processing and will become established in companies in the future.

First model, then realise

Our head of sales of fe.screen, Werner Pospiech, provides an interesting insight into the world of virtual commissioning in the special chapter "Factory Planning and Commissioning" of the trade journal "IT&Production".

Challenges faced when introducing virtual commissioning

The introduction of a VC solution in a company is connected with a number of challenges. Knowing these challenges and the development of own strategies contribute to the success of the first project.

Driving digitalization through plant simulation and virtual commissioning

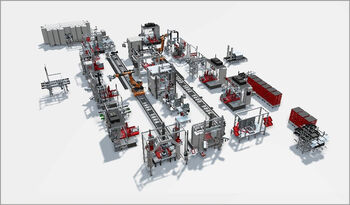

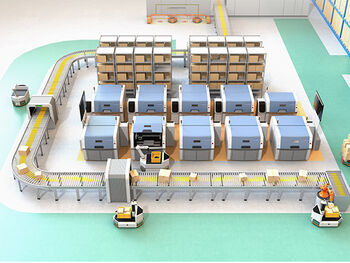

Conventional commissioning of complex plants and machines can cause considerable cost and time expenditure. Especially when they do not run as planned. With "virtual commissioning", a so-called "digital twin" of the plant is created by importing the design data before the real assembly and commissioning.

![[Translate to EN:] three pillars for the creation of a digital twin three pillars for the creation of a digital twin](/fileadmin/_processed_/3/6/csm_drei-saeulen-digitaler-zwilling-en_01_8ba73c5c94.jpg)

The three pillars of digital twins

The simulation solution fe.screen-sim differs in many essential points from other tools that are used to create plant models and the associated virtual commissioning.

Software news and trade fair reports

Below you will find all the information on innovations relating to the fe.screen-sim simulation tool.

![[Translate to English:] F.EE_SPS_2024_Coligo_IPI_Gruppenfoto](/fileadmin/_processed_/a/0/csm_F.EE_SPS_2024_COLIGO_IPI_01_a1d4c13193.png)

SPS trade fair 2024: F.EE takes positive stock

F.EE was represented at the SPS trade fair in Nuremberg with the fe.screen software series and the ERP system FactWork.

Give me five: Innovations in virtual commissioning

F.EE presents new V5 of the simulation tool ‘fe.screen-sim’ at the SPS in NurembergF.EE presents new V5 of the simulation tool ‘fe.screen-sim’ at the SPS in Nuremberg.

Successful collaboration sealed

Ulf Scheuchl, Managing Director of R. Scheuchl GmbH, and F.EE Managing Director Hans Fleischmann used this year's SPS trade fair to seal the successful cooperation with the virtual commissioning solution "fe.screen-sim".

Welcome to SIM.ACADEMY

Browse through a variety of different tutorials as well as videos on already realized projects and the latest features of the simulation software "fe.screen-sim" in the new "SIM.ACADEMY". In addition, you have the opportunity to experience the simulation tool in practice in online webinars and workshops and to get to know the latest features. In the documentation section we provide you with helpful documents. So, let's get started!

Easy creation of simulation models from CAD and new features in fe.screen-sim V4

CAD data of plants are available in the form of 2D or 3D data. In essence, however, no thought has ever been given during design to being able to make this data available to other systems, such as a simulation environment. So how can simulation models of plants be created easily and quickly?

fe.screen-sim: Bidirectional data exchange with "Process Simulate

An essential prerequisite for achieving data consistency in model creation is the flexible use of existing data sources and their data structures.

Range of services expanded

Consulting, training and support: We now provide newcomers to plant simulation with targeted support for their digitization projects.

fe.screen-sim v4 gets new interface to MATLAB® and Simulink®

The version V4 of the F.EE solution for Digital Twins gets a new interface to MATLAB® and Simulink®, which will be presented for the first time at the SPS IPC Drives trade fair on November 27 in Nuremberg. Thus, numerical calculations based on MATLAB® as well as the modeling of technical and physical systems using Simulink® can be integrated within the scope of a simulation.

Virtual commissioning closer to reality than ever: New version 4 of fe.screen-sim available

The 3D simulation software for increased efficiency, plannability and risk minimization during the commissioning of machines and systems in the areas of materials handling, logistics, mechanical engineering and robotics makes a quantum leap with Version 4.0 - both in terms of functionality and in terms of appearance and fidelity to reality.

Quantum leap in virtual commissioning and new cooperation presented in Nuremberg

The fe.screen-sim software solution was a real visitor magnet at the SPS IPC Drives trade fair 2018. A new partnership with ABITRON GmbH, a leading manufacturer of wireless remote controls in the industrial sector, ensures the possibility to use fe.screen-sim e.g. for virtual crane training including realistic vibration behavior of the load. Trade fair visitors had the opportunity to extensively test this live on site and by means of virtual reality and to prove their skills as virtual crane operators in the 3D environment.

Your personal contact person – for more clearness

You are a project or department manager and are faced with the question of how to set up a digital twin for your project? We would be happy to talk to you personally about your requirements, the time frame, the possible project approach and give you an initial cost estimate.