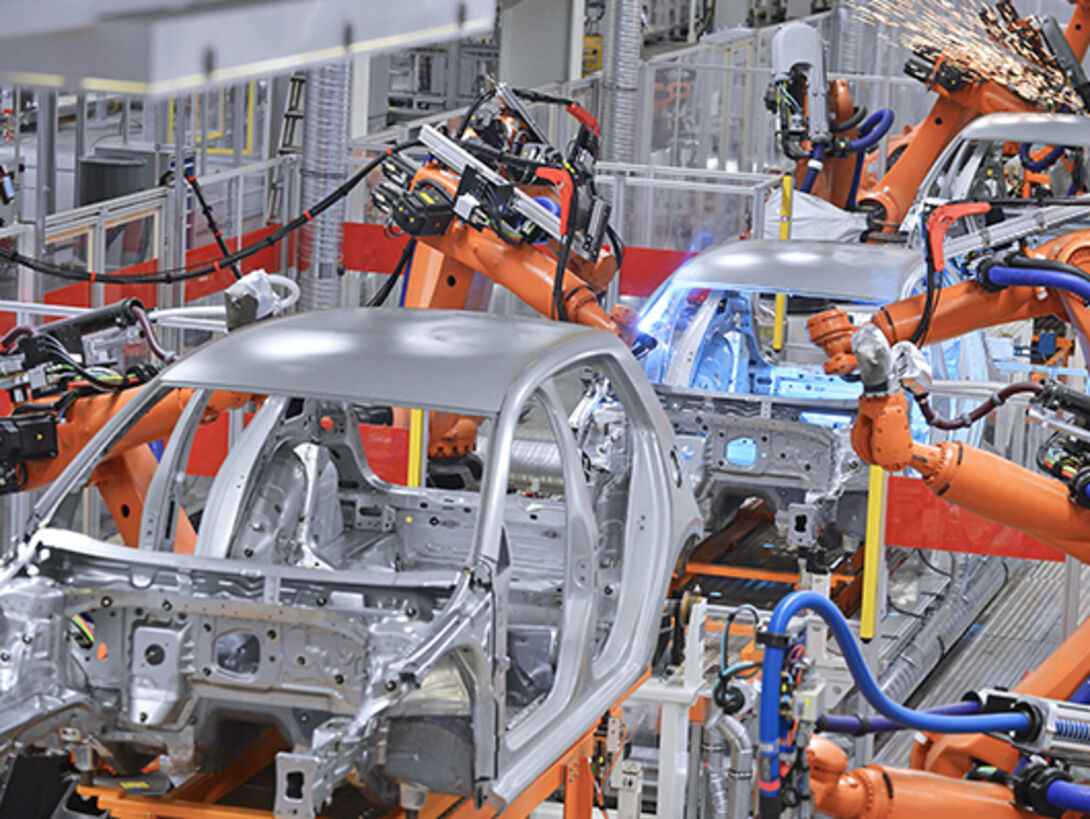

Mechanical engineering: Simulation of assembly and production plants

In the mechanical engineering industry, where complexity and time play an important role, the use of fe.screen-sim brings many advantages. The early detection and correction of errors is the goal. With the help of 3D simulation, for example, costly and time-consuming machine collisions are ruled out from the outset. Thanks to precise planning and simulation, the most efficient assembly and production automation is achieved. The digital twins help designers, planners and automation engineers as well as operators.

The approach

NC programs can be analyzed and verified before the machine is completed. Due to the intuitive combination of existing simulation elements, fe.screen-sim can be used to simulate machines with any number of axes. Adjustments in the development phase, process safeguarding and validation for error avoidance, virtual operation, software and disturbance scenario tests, as well as the minimization of test cycles on machine prototypes are thus possible. During the instruction of the machine operators on the digital twin, the best possible understanding of the functionalities is also conveyed. This reduces training and set-up times on the real system and saves costs.

SIMPLE Import OF SIMULATION MODELS directly from CAD

CAD data is available in the form of 2D or 3D data and, in order to start a simulation, must be imported into the simulation environment as losslessly as possible. fe.screen-sim supports both the import of various exchange formats, such as STEP, JT, IGES, OBJ, etc., as well as the native import of data, e.g. from SolidWorks, CATIA or CREO. An import of AML data including kinematic information is also possible.

Additional information required for the creation of a simulation model often lies in other data sources such as Excel, Visio or databases. Our software can tap into different data sources using an API and automatically create a simulation model.

A bidirectional data exchange is possible: If you change data in the simulation, these changes are also transferred to the CAD system or its subsystems. Thereby, fe.screen-sim can be adapted to the existing data structures and the data does not have to be changed to create a simulation model.

SOLUTIONS – SIMULATION CAN BE USED HERE

Assembly systems of all kinds (rotary cycle, longitudinal cycle, etc.), Robot assembly, systems and robot cells, Handling systems for electronic components, Placement systems, Interlinked production and assembly systems, Machine tool plants, Packaging systems, Test plants, Plants for woodworking, and many more.

Your personal contact person – for more clearness

You are a project or department manager and are faced with the question of how to set up a digital twin for your project? We would be happy to talk to you personally about your requirements, the time frame, the possible project approach and give you an initial cost estimate.