Schaeffler Special Machinery: More horsepower through virtual commissioning

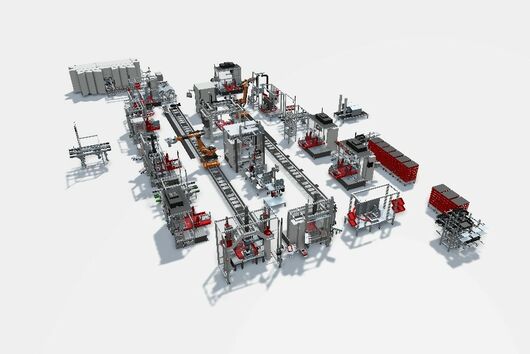

For over 75 years, the Schaeffler Group has been driving forward pioneering inventions and developments in the field of motion technology. Part of this success is to supply technologies, products and services to customers from a wide range of industrial sectors from a single source. With this in mind, Schaeffler Special Machinery plans and designs assembly systems, testing systems, processing machines and handling technology, manufactures them in its own plants and commissions them for end customers all over the world. The rapid technical developments in automation and digitalisation increasingly require solutions that take account of the growing complexity of systems and projects.

The F.EE group of companies from Neunburg vorm Wald in the Upper Palatinate - a company specialising in production automation and industrial IT - developed fe.screen-sim, a simulation tool for the virtual commissioning of machines and systems. With this software, F.EE has also created a number of important possibilities for Schaeffler Special Machinery: In addition to safeguarding the control software, critical operating states can be tested risk-free and complex processes can be simulated in an early project phase. The experts at Schaeffler Special Machinery now validate and optimise the control and regulation strategies of their systems as early as the engineering phase, thereby saving valuable capacities, as Dominik Broszeit, software developer at Schaeffler Special Machinery in Erlangen, explains. ‘Compared to the past, the timeline for the development of special machinery is significantly shorter and at the same time is spread over many more heads.

Increasing complexity and time pressure: a challenge not only for Schaeffler Special Machinery

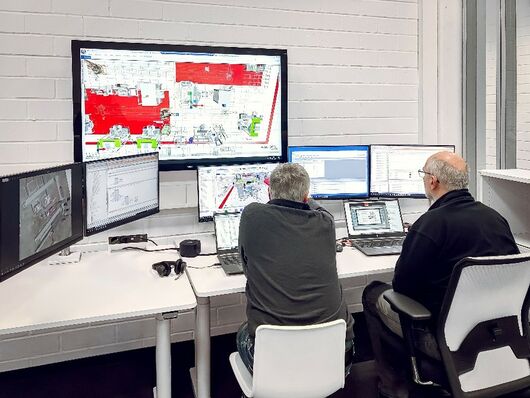

‘We realised that we could only meet the complex market requirements and the desire for faster delivery of fully functional systems if everyone involved could work on a project in parallel. Virtual commissioning with fe.screen-sim therefore plays a key role,’ explains Stefan Gahabka, Head of Electrical Engineering at Schaeffler Special Machinery. The tool with its sophisticated multi-user capability enables him and his team to work simultaneously with several users and thus write and test the software for a system yet to be built at the earliest possible stage. ‘We are fully operational, even though procurement and assembly have only just started,’ explains mechatronics engineer Broszeit. The time gained flows into programming and testing and enables measurably higher quality: whereas previously the test runs only took place after all the work had been completed and caused both deadline pressure and stress, it is now possible to start immediately - many processes can be brought forward, which means significant relief for the team at the end of the project or during commissioning at the customer's premises.

Product development and system planning: now it even works in parallel

What's more, the software enables simultaneous engineering. Today, systems for products are often designed when the products are not yet 100 per cent fully developed in order to be able to go into series production quickly.

One thing is nevertheless particularly important to software expert Broszeit: as great as the leaps in development in the field of virtual commissioning are, it is also important to recognise and deal with areas of uncertainty: ‘We will never be able to completely replace digital commissioning. But we at Schaeffler don't have this claim either. We are at up to 95 per cent and thus measurably save a lot over the entire development and commissioning process.

Not a newcomer: simulation software fe.screen-sim

About two years ago, Schaeffler Special Machinery identified the need to change the existing software for virtual commissioning. After comparing various tools, the decision was made in favour of fe.screen-sim. Dominik Broszeit was already familiar with the software from his studies. It was there that he first became involved with virtual commissioning and even gained a master's degree in this field. He has had good experiences with fe.screen-sim, which he attributes primarily to its intuitive operation - and the performance has also impressed him and his team. Particularly in view of the fact that Schaeffler's production systems are becoming increasingly complex and the data volumes are therefore growing, simple data handling, simple operation and open interfaces are equally important to Broszeit.

One for all: fe.screen-sim relieves all trades

‘My understanding of a good simulation is that we use a tool like fe.screen-sim to bring all trades to the virtual table,’ emphasises the expert. The challenge: mechanics, electricians and programmers all speak a different language and usually use different data formats. His understanding of teamwork: tool-supported, efficient work in conjunction with successful simulation creates advantages and involves everyone. He also emphasises that F.EE always thinks and acts in a solution-oriented way: ‘If we call them and say that we need an additional interface for a project, it works.’

We are the new ones: How Schaeffler introduced the simulation software

Together, everyone is required to orientate themselves on existing structures and processes in mechanics or electrics for the introduction of the simulation software. He has not experienced any reservations from the specialist departments about the new tool: ‘Our main area of application is still software testing.’ The commissioning engineer can test and optimise the system from anywhere in the world - including Erlangen or his home office. The elimination of travelling times also reduces the workload for employees. It also simplifies the search for experienced commissioning engineers: Today, it is all too often not only the lack of skilled labour that is a challenge, but also the willingness to be away from the family for long periods of time.

The figures speak for themselves

The success proves Schaeffler right: over the past two years, Broszeit and his colleagues have successfully put a number of plants into virtual operation.

And there is more to come. The next step is to store plant models centrally in a protected network and make simulations available as a service to all Schaeffler colleagues worldwide. This is made possible by networking the simulation tool with other systems - such as robots, drives or control systems. With fe.screen-sim's own separation between core and client, this runs smoothly - the core runs on the host and the developers are the clients.

Virtuality dissolves borders and connects worldwide

The practical test proves that the plan is working: in a joint project with the Schaeffler Special Machinery site in China, Chinese and German developers recently worked on a joint virtual model. The most important thing is to set up the digital model at the earliest possible stage, which can then be accessed by all the trades involved. This approach creates further opportunities for Schaeffler Special Machinery to utilise fe.screen-sim. Quality assurance is one such area. The simulation tool can deliver added value for service providers and customers alike by equalising time-critical commissioning at the customer's premises and speeding up many processes - so the prospects for the future are good.

The author Werner Pospiech is Sales Manager for industrial software (fe.screen-sim) at F.EE GmbH

Source of all photos/images: Schaeffler AG

Your personal contact person – for more clearness

You are a project or department manager and are faced with the question of how to set up a digital twin for your project? We would be happy to talk to you personally about your requirements, the time frame, the possible project approach and give you an initial cost estimate.