Give me five: Innovations in virtual commissioning

F.EE presents new V5 of the simulation tool ‘fe.screen-sim’ at the SPS in Nuremberg

‘Give me five’ - This slogan not only stands for the invitation to give each other a high five, e.g. due to a success or congratulations, but also forms the motto of the F.EE group of companies for the introduction of the new version 5 of the simulation tool fe.screen-sim. Managing Director Hans Fleischmann explains why this is the case: ‘We decided on the slogan “Give me five” not only because of the version number, but also because we want to give ourselves and our users a symbolic “high five” for the new possibilities and features. Version 5 marks a milestone in the creation of digital twins.’

The new V5 will be presented for the first time at this year's SPS trade fair from 12 to 14 November in Nuremberg. The F.EE developers will be presenting innovations for virtual commissioning in particular - especially in terms of performance, rendering, robot simulation and data analysis.

Performance and rendering on a new level

fe.screen-sim V5 will set new benchmarks, particularly in terms of performance. ‘Here we are making the previously impossible possible and achieving a new maximum,’ says Hans Fleischmann. The basis for this is the fact that F.EE develops the rendering independently as a central component of the simulation. In addition to considerable performance advantages, this also results in a flexible and highly optimised display for simulations. As rendering has a significant influence on the optimum utilisation of a graphics card, F.EE's proprietary technology enables particularly efficient and fluid display - even of highly detailed CAD models.

In addition to the increase in performance, the new rendering also brings with it many visual innovations and improvements. The systems can be displayed almost photorealistically. Thanks to ray tracing technology, the visualisation of elements including lighting, shadows and reflections is more realistic than ever before ‘When it comes to rendering, we rely on a combination and improvement of different methods and algorithms. This allows us to achieve new levels of performance and visualisation quality. This not only benefits users when creating digital twins, but also other departments involved in the engineering and project process,’ says Peter Meier, Head of the “Software Development Simulation and Virtual Commissioning” department at F.EE, explaining the advantages of the new rendering technology.

More robots, maximum synergy

A lot has also happened in the area of robot simulation with version 5. Here, F.EE is cooperating with the company ‘Robo DK’, among others. ‘Thanks to the innovative plug-in, robots can now be integrated into fe.screen-sim even more easily and intuitively - regardless of type or manufacturer: the robots can be easily programmed, simulated and thus fully tested. All interactions and interfaces are thus tested in advance in the overall network. The collaboration with ‘Eleven Dynamics’ also makes it possible to optimise robot paths using AI.

It is now possible to simulate hose packages on robots in fe.screen-sim. ‘As an automation specialist, we at F.EE know from our own experience that small details often determine the success of complex projects. That's why we attach so much importance to continuously increasing the level of detail in our simulation software,’ says company founder Hans Fleischmann. Hose assemblies can cause delays and costs in a project if they collide with other objects in the system and are only discovered during actual commissioning. The V5 provides a remedy here and enables a simulation including this detail in a simple way.

The time machine in the simulation

V5 also has another detail with implications for practical work with digital twins. ‘We have integrated a controller into fe.screen-sim that allows you to play with time, so to speak,’ explains Head of Development Peter Meier. This offers completely new analysis possibilities: By slowing down the physical processes, very fast processes can be analysed in slow motion. At the same time, processes that often take hours, days or weeks can be displayed in fast motion, allowing entire production days to be simulated in a short space of time, for example.

Effective data analysis on the digital twin

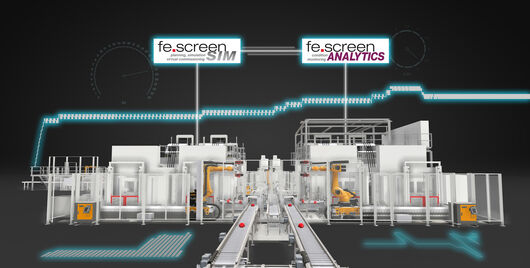

An additional highlight is the fact that the condition monitoring tool ‘fe.screen-analytics’, another industrial software product from F.EE, has now been connected to the simulation software, thereby bundling expertise across all areas. ‘This new interface opens up exciting possibilities in terms of data analysis in virtual commissioning. Thanks to the exchange between fe.screen-sim and fe.screen-analytics, data and measured values can be displayed live in the simulation, perfectly analysed and systems can be tested even more efficiently.

The recorded data can be saved and different scenarios can be compared with each other on the basis of the collected analysis data, allowing the maximum throughput to be determined for the simulated systems. Users of fe.screen-sim benefit from the fact that the optimisation of systems has been one of F.EE's core competencies for decades and the company can draw on an enormous wealth of experience in this area.

‘With the new version 5, fe.screen-sim is developing even more into a holistic, practice-orientated and future-proof system for virtual commissioning and beyond. We are sure that the new features will convince many companies and that the motto ‘Give me five’ can be taken literally,’ summarises the F.EE Managing Director.

Come and see the new features at SPS in Hall 6, Stand 308!

Your personal contact person – for more clearness

You are a project or department manager and are faced with the question of how to set up a digital twin for your project? We would be happy to talk to you personally about your requirements, the time frame, the possible project approach and give you an initial cost estimate.